Within product packaging, foam inserts serve as critical protective components directly impacting product safety during transit and storage. Leveraging XPE, IXPE and IXPP high-performance materials, Bofeng Foam delivers bespoke foam insert solutions.

1. XPE Foam Inserts

Material Properties

- Closed-cell structure with uniform density

- Superior cushioning and rebound performance

- Waterproof, moisture-resistant, and chemically durable

Application Features

- Precision electronics packaging: Frame padding for smartphones and tablets

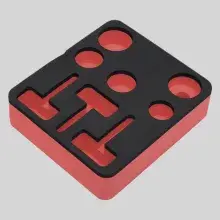

- Industrial equipment inserts: Custom die-cut inserts for precision instruments and mechanical components

- Cold chain packaging insulation: inner thermal layer for insulated containers

Customisation Advantages

- Supports precision die-cutting for complex inner structures, delivering accurate cushioning protection.

2. IXPE Foam Inner Lining

Material Properties

- Electron beam cross-linking process for finer, more uniform cell structure

- Excellent anti-static properties

- High resilience and durability

Inner Insert Application Features

- Medical device packaging inserts: Sterile packaging for surgical instruments and diagnostic equipment

- Premium electronics inserts: Anti-static packaging for semiconductor components and precision circuit boards

- Food packaging inserts: Hygienic-grade padding for food processing equipment

Customisation Advantages

- Anti-static agents can be incorporated for permanent protection, suitable for cleanroom environments.

3. IXPP Foam Inserts

Material Properties

- Enhanced rigidity and structural support

- Superior heat resistance (up to 120°C)

- Lightweight yet high strength

- Ageing resistance for extended service life

Insert Application Highlights

- Automotive component packaging inserts: Structural padding for engine parts and electronic control units

- Heavy equipment inserts: Support frames for industrial tools and large instruments

- Reusable packaging inserts: Durable linings for logistics containers

Customisation Advantages

- Suitable for creating composite inserts requiring structural support, reusable to reduce packaging costs.

Application Examples

- Consumer electronics: Ultra-thin IXPE shock-absorbing inserts for smart wearables

- Medical devices: Custom XPE composite inserts for surgical robot accessories

- Industrial Manufacturing: IXPP structural transport inserts for automotive components

Leveraging years of industry expertise and technological advancement, Bofeng Foam delivers comprehensive foam insert solutions—from material selection and structural design to production processing. Contact us for professional packaging advice and bespoke services.

Email: jason.zhan@bofmat.com